Engineered Foams

Your high-performing and lightweight solution

Why engineered foams matter

Engineered foam is a versatile material that is widely used across industries because of its lightweight and robust properties. In the transportation industry, engineered foam provides effective thermal and acoustic insulation in composite panels used in trains, trucks, and trailers, ensuring passenger comfort and noise reduction. In the energy sector, recycled PET foam plays an essential role in wind turbines, contributing to the overall efficiency of energy production and transformation applications. Additionally, component foams made of elastomeric and polyolefin materials, hold important functions in the technical market, providing high-performance solutions for sound attenuation in OEM equipment and waterproof sealing in building construction and infrastructure projects. Our comprehensive offering of innovative foam product solutions is designed to meet all these needs, including structural and insulating foam cores, thin, flexible sheets for thermoformable micro sandwich solutions and particle foams to produce 3D foam parts.

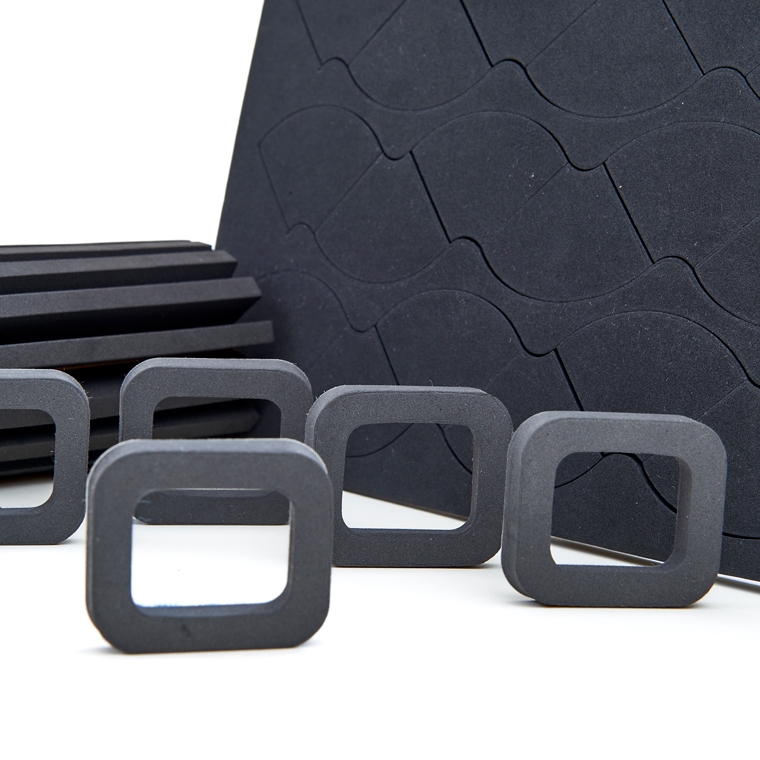

Component foams for many markets

Armacell's component foam division is the global leader and innovator in expanded cellular foam products delivering decades of product knowledge and innovation to our partners in the automotive, heavy equipment, transportation, industrial, medical, and sport and leisure markets. Our ArmaComp® product lines consist of elastomeric and polyolefin products for a wide range of market applications. Our foams can be used in gaskets and seals, padding, and vibration control among other applications. You’ll find many foam products are compliant with existing market specifications and fire safety standards. With sales and technical teams who are willing to help you find just the right material, Armacell’s ArmaComp portfolio has a product range that’s second to none.

From bottle to foam, turning single use plastics into high-value foam core materials

Our PET foam solution is based on a pioneering process, allowing us to transform post-consumer PET bottles into high-value foam core materials for composite structures that can be fed back into the production cycle in a true, circular economy. Dive deeper into the technology behind PET-based foam and its distinctive characteristics.

Noise and acoustic comfort in rail transportation

Curious to learn more about meeting common rail construction challenges with advanced thermal and acoustic insulation? In our whitepaper, we explain how to identify the right insulation materials to reduce disturbing noise and ensure optimal passenger comfort.

Your holistic partner and advisor

Your holistic partner and advisor

We understand that every plant room layout is unique. As an experienced partner in mechanical insulation, we are committed to finding the right insulation solution for your project – from insulation materials to adhesives and accessories as well as claddings and pre-covered products. By sharing our system expertise and technical know-how, we provide you with a complete overview of your insulation system to achieve your desired thermal performance and energy-saving target.

Rely on high quality and durability

Rely on high quality and durability

The insulation you choose must be durable to withstand wear and tear and achieve maximized lifetime performance. As a global leader in insulation materials, we deliver the highest quality and longevity, conducting more than 30,000 quality tests each year and constantly optimizing our materials to offer best-in-class solutions for your projects.

Lower your total cost of ownership

Lower your total cost of ownership

Insulation is essential to the operational reliability of mechanical equipment. To avoid high maintenance, repair, and consequential costs, the technical performance and reliability of the installation must always be the deciding factor when selecting equipment insulation. Our comprehensive range of high-performing system solutions and products ensures long-term reliable results. Armacell materials allow for spot repairs, ensuring that if properly installed sections are damaged, they can be restored to their original efficiency. This extends the life of the insulation and reduces the need for costly full-scale replacements, significantly lowering maintenance and repair expenses over the lifetime of the insulation.

Get installation support

Get installation support

We believe that insulation material is only as valuable as the quality of its installation. That’s why we are continuously building a growing network of certified installers, ready to use our high-quality materials effectively and professionally. Our dedicated Armacell trainers offer structured on-site and off-site training courses and certifications, complemented by self-service tools, including application manuals and videos to support installers and contractors during specification, installation and maintenance.