Mechanical insulation for instrument lines

Meeting a growing demand for flexible solutions

Master small diameter process lines

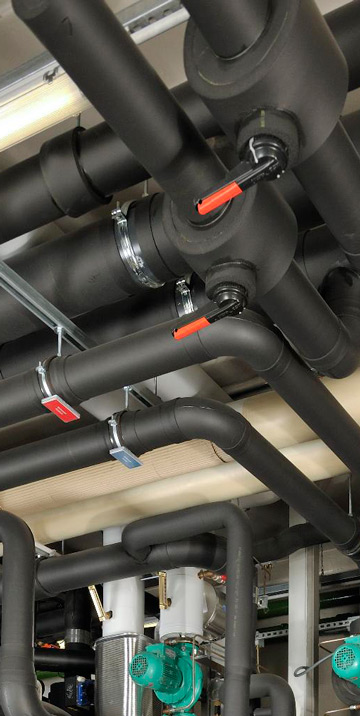

Insulated instrument lines are a crucial part of the industrial pipeline network and are needed to ensure the safe transfer of energy and other substances across the industrial plant. Creating fully insulated pipe infrastructure can, however, become a complex task as diameters are often smaller than in conventional process lines. At Armacell, we specialize in flexible insulation materials that can easily fit all diameters and angles, ensuring a convenient and effective insulation solution for instrument lines of any size.

Flexible materials for easy application

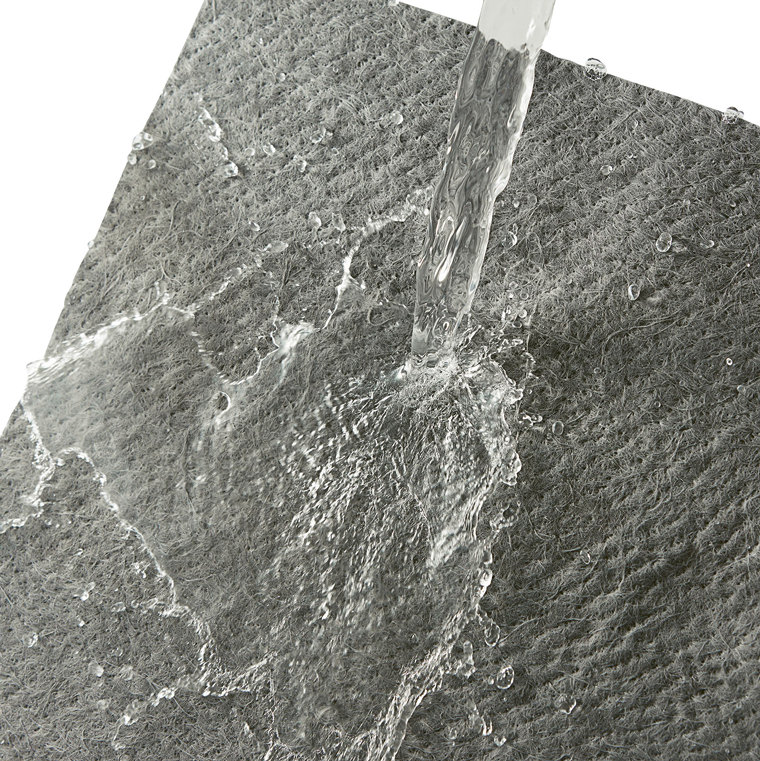

Industrial applications present unique environments. As space is limited and pipes may not be accessible from all angles, insulation solutions need to be adaptable and easy to install. The flexible properties of elastomeric foam and innovative aerogel technology ensure efficient fittings for pipe elbow and t-pieces. By using preformed tubes, installers benefit from practical and easily applied solutions, reducing installation time and costs.

Effective condensation control

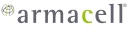

Industrial environments are characterized by extreme temperatures that range from -196 °C (-321 °F) up to +650 ºC (+1200 ºF). In these conditions, ensuring effective condensation control is key to ensuring personal safety and protecting surrounding equipment. Closed-cell foam applications balance thermal conductivity with space constraints and water vapor resistance, offering reliable protection against condensation. This enhances safety by reducing the risk of accidental burns from hot pipes and also protects the integrity of the system. The hydrophobic properties of ArmaGel® allow equipment to stay drier for longer by repelling liquid water.

Energy efficiency in smaller surface applications

Instrument lines typically have a smaller surface area compared to larger process pipelines. As a result, energy losses can be smaller but still significant. Our insulation products are designed to deliver high efficiency, ensuring that even with smaller surface areas, energy losses are minimised. By effectively insulating instrument lines, specifiers can contribute to overall resource savings and meet energy efficiency requirements.

Acoustic control for enhanced comfort

In industrial settings, acoustic control can be essential for worker health, comfort and productivity. We recognize the importance of noise reduction in instrument lines and offer insulation materials that help to significantly mitigate noise levels, contributing to a quieter, safer and more comfortable working environment.

Your holistic partner and advisor

Your holistic partner and advisor

We understand that every plant room layout is unique. As an experienced partner in mechanical insulation, we are committed to finding the right insulation solution for your project – from insulation materials to adhesives and accessories as well as claddings and pre-covered products. By sharing our system expertise and technical know-how, we provide you with a complete overview of your insulation system to achieve your desired thermal performance and energy-saving target.

Rely on high quality and durability

Rely on high quality and durability

The insulation you choose must be durable to withstand wear and tear and achieve maximized lifetime performance. As a global leader in insulation materials, we deliver the highest quality and longevity, conducting more than 30,000 quality tests each year and constantly optimizing our materials to offer best-in-class solutions for your projects.

Lower your total cost of ownership

Lower your total cost of ownership

Insulation is essential to the operational reliability of mechanical equipment. To avoid high maintenance, repair, and consequential costs, the technical performance and reliability of the installation must always be the deciding factor when selecting equipment insulation. Our comprehensive range of high-performing system solutions and products ensures long-term reliable results. Armacell materials allow for spot repairs, ensuring that if properly installed sections are damaged, they can be restored to their original efficiency. This extends the life of the insulation and reduces the need for costly full-scale replacements, significantly lowering maintenance and repair expenses over the lifetime of the insulation.

Get installation support

Get installation support

We believe that insulation material is only as valuable as the quality of its installation. That’s why we are continuously building a growing network of certified installers, ready to use our high-quality materials effectively and professionally. Our dedicated Armacell trainers offer structured on-site and off-site training courses and certifications, complemented by self-service tools, including application manuals and videos to support installers and contractors during specification, installation and maintenance.

Discover our Installation Training

Our commitment to providing high-performing insulation technology goes beyond high-quality materials. It involves sharing our expertise on the right installation of our insulation systems. In our training programs, we equip you with the necessary expertise to install our solutions reliably, safely, and quickly.